In today’s world, where technological innovations are realised at an incredible speed, design and analysis methods in shipbuilding are also subject to constant change. One of the most efficient and reliable methods of analysis has become the finite element method (FEM). This approach gives shipbuilding engineers a wide range of capabilities to analyse various aspects of designed vessels, from structural elements to the complex systems and devices on board. The finite element method is an indispensable tool in modern shipbuilding.

The finite element method is a numerical method for solving differential equations arising in calculations of various physical and engineering problems. This method decomposes an object or system into a set of “finite elements” and performs calculations for each of them, taking into account their interactions.

Advantages of FEM application in shipbuilding

High calculation accuracy

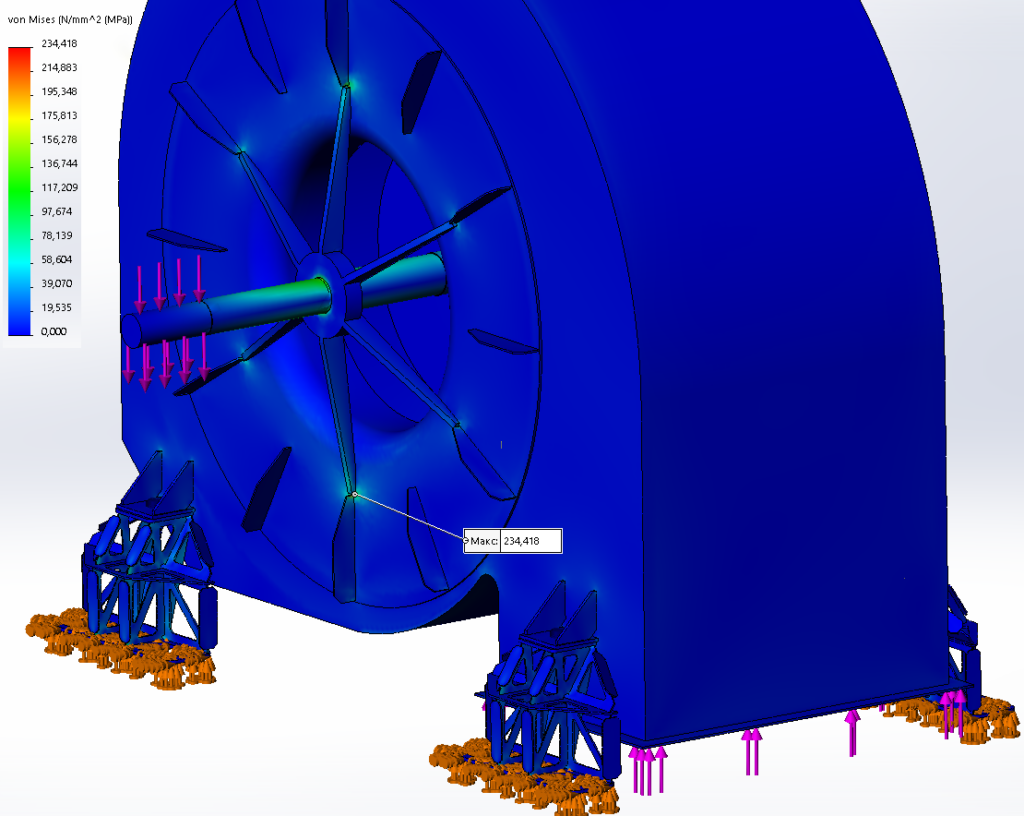

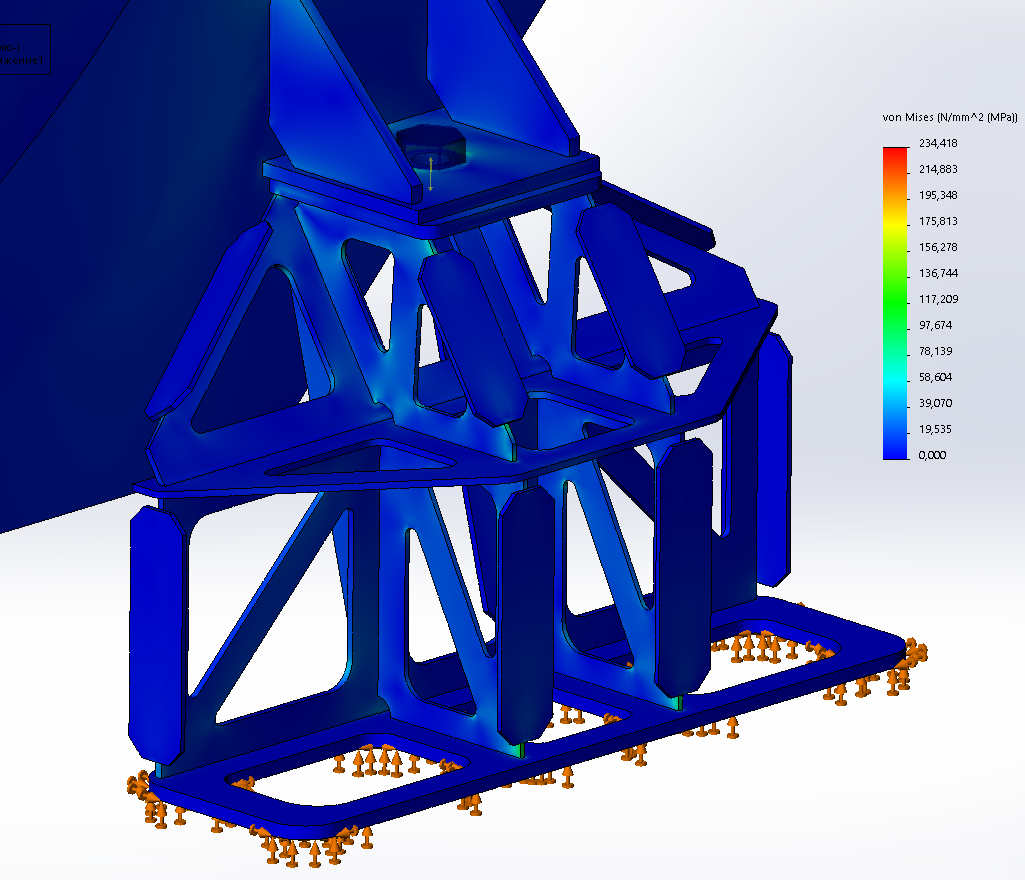

The finite element method provides an incomparably high level of accuracy. This is particularly important in ship design, where even small errors can have serious consequences. FEM allows complex factors such as non-linear material properties and dynamic loads to be taken into account.

Saving time and resources

Traditional analysis methods require physical prototyping and testing, which is time-consuming and expensive. FEM provides the ability to virtually simulate various operating conditions, which significantly reduces the cost of producing physical prototypes and testing them.

Versatility and flexibility

The FEM can be used to analyse a variety of different types of structures and materials, making it an ideal tool for shipbuilding where many different materials and structural solutions are used.

Design optimisation

FEM can be used to analyse and optimise various ship parameters such as strength, stability and hydrodynamic performance.

Improved safety

The FEM allows predicting the vessel’s behaviour under extreme conditions such as storms or collisions, which helps to implement the necessary safety measures.

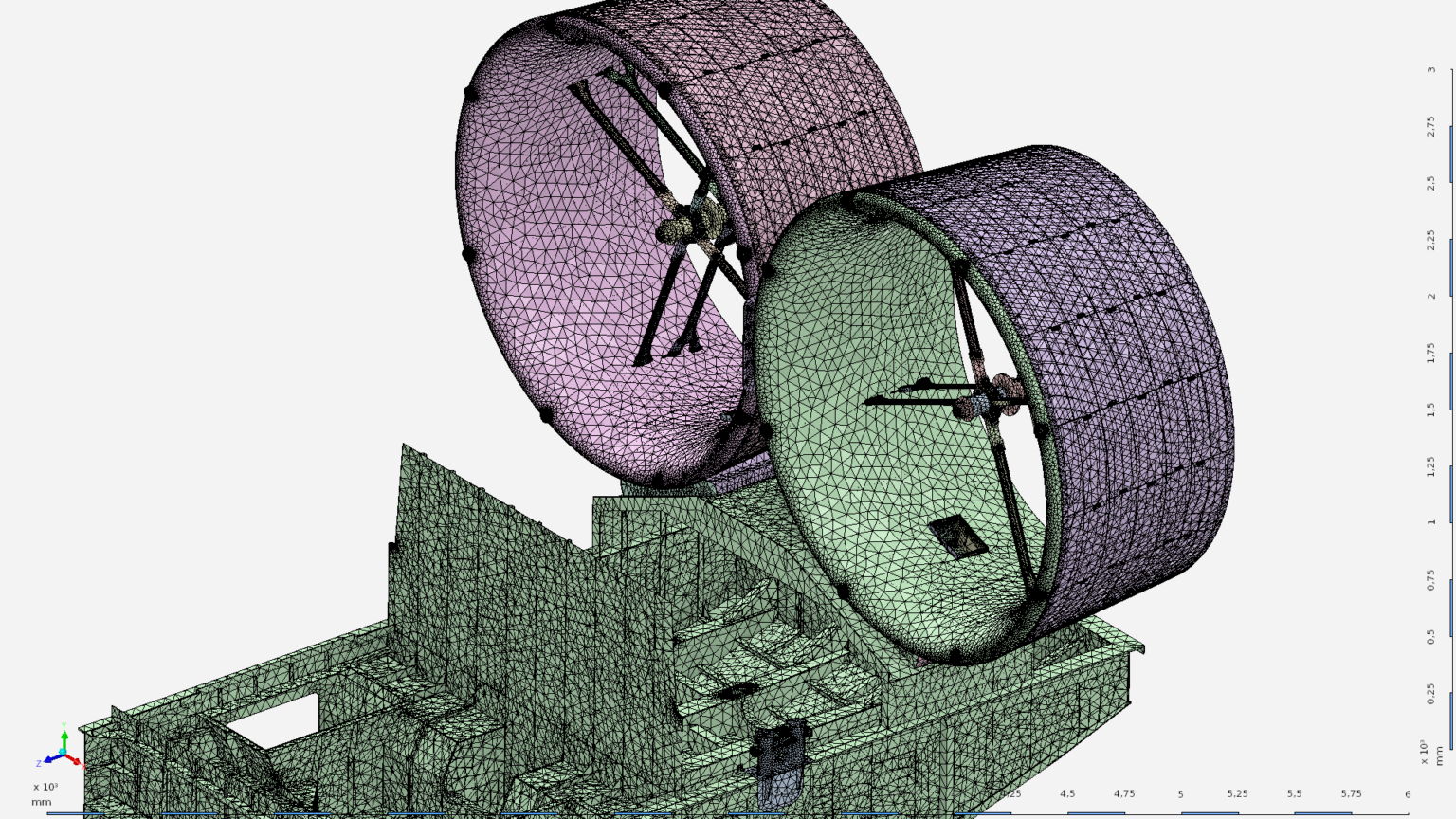

FEM application in the design bureau of "IMT Design Bureau" LLC

In our design office, IMT Design Bureau LLC, the finite element method is widely used at various stages of ship design. This approach not only improves the quality and efficiency of our projects, but also enables our engineers to solve complex problems that often arise during the design process.

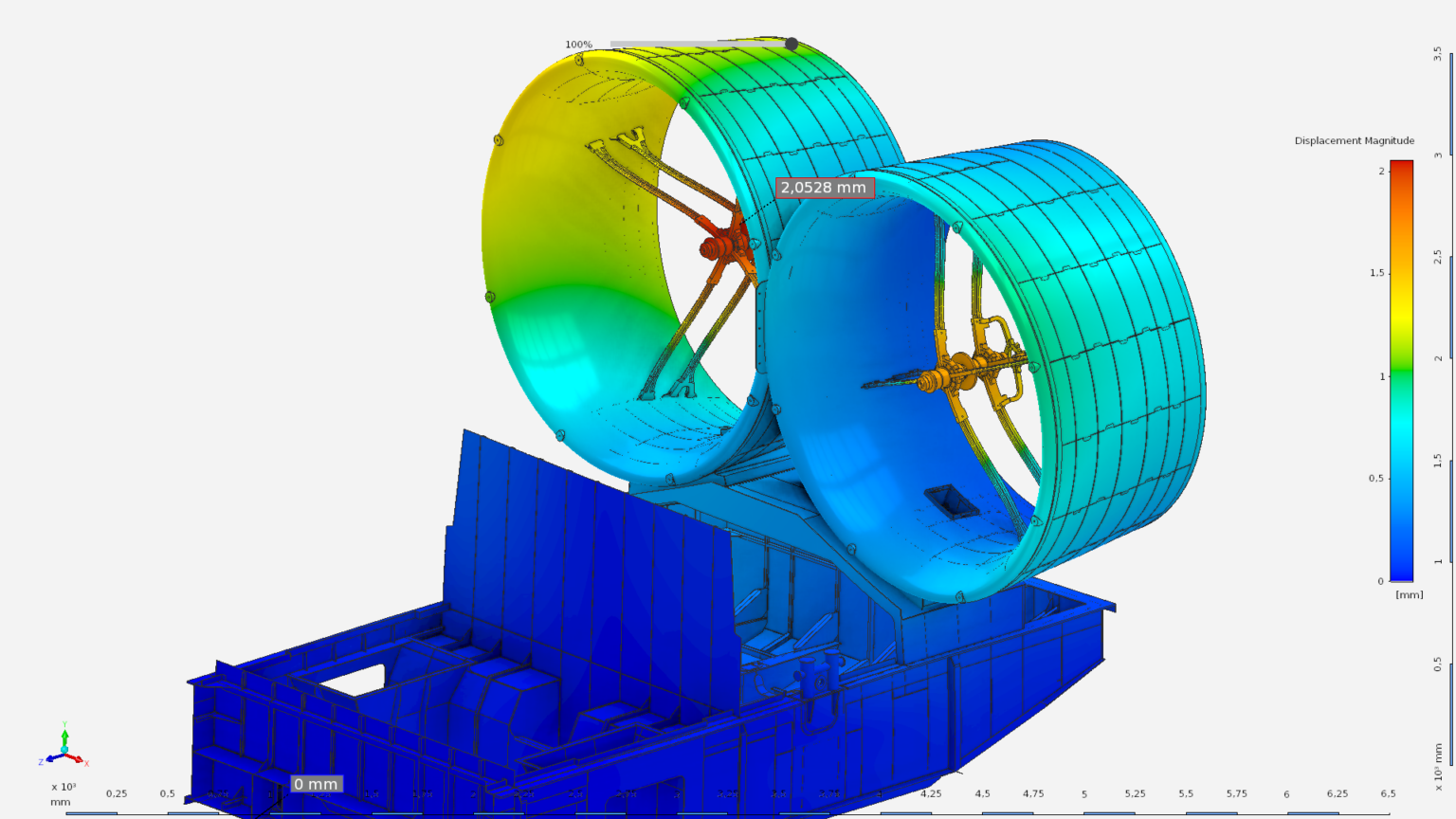

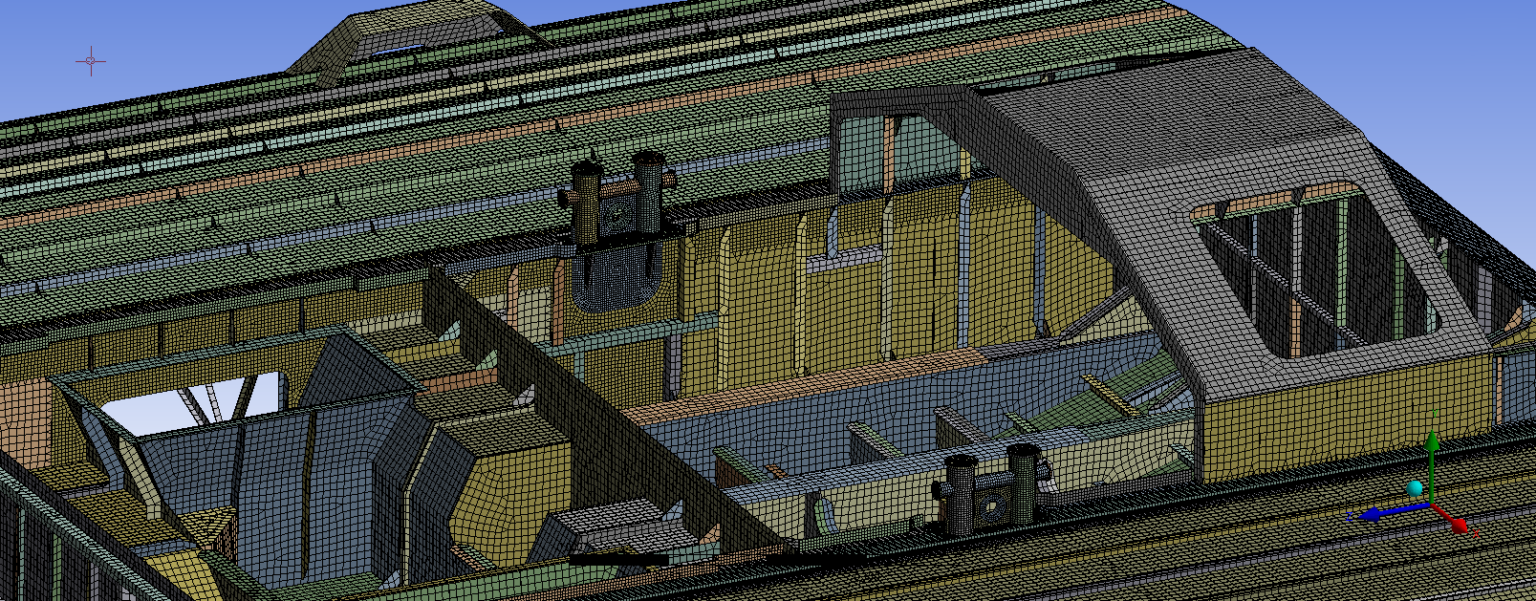

Engineers of IMT Design Bureau LLC use FEM not only to analyse the overall strength of a vessel, but also to test its individual elements, structures and devices. This allows to determine optimal materials and geometric parameters, as well as to carry out a comprehensive analysis of their interaction with other elements of the vessel.

With the help of FEM, our team is able to perform fast and accurate calculations, which significantly reduces design time and allows us to focus on innovation. As a result, vessels designed by IMT Design Bureau LLC are highly reliable, durable and efficient.

At IMT Design Bureau LLC, we pride ourselves on using advanced methods and technologies, such as the finite element method, to create modern, efficient and safe offshore vessels. This is not just following a trend, but a conscious choice in favour of quality, economy and innovation.