Every day marine engineers and ship designers are faced with increasing challenges and demands. One of the key elements of successful ship design is the application of Computational Fluid Dynamics (CFD).

Computational Fluid Dynamics is one of the important tools of our business that we apply in the knowledge-intensive design of ships and their components. We believe that the use of modern technology and advanced analyses helps us to create vessels that truly outperform the competition. Our team of engineers and researchers are strong in this field and apply computational fluid dynamics to all stages of design from conceptual design onwards.

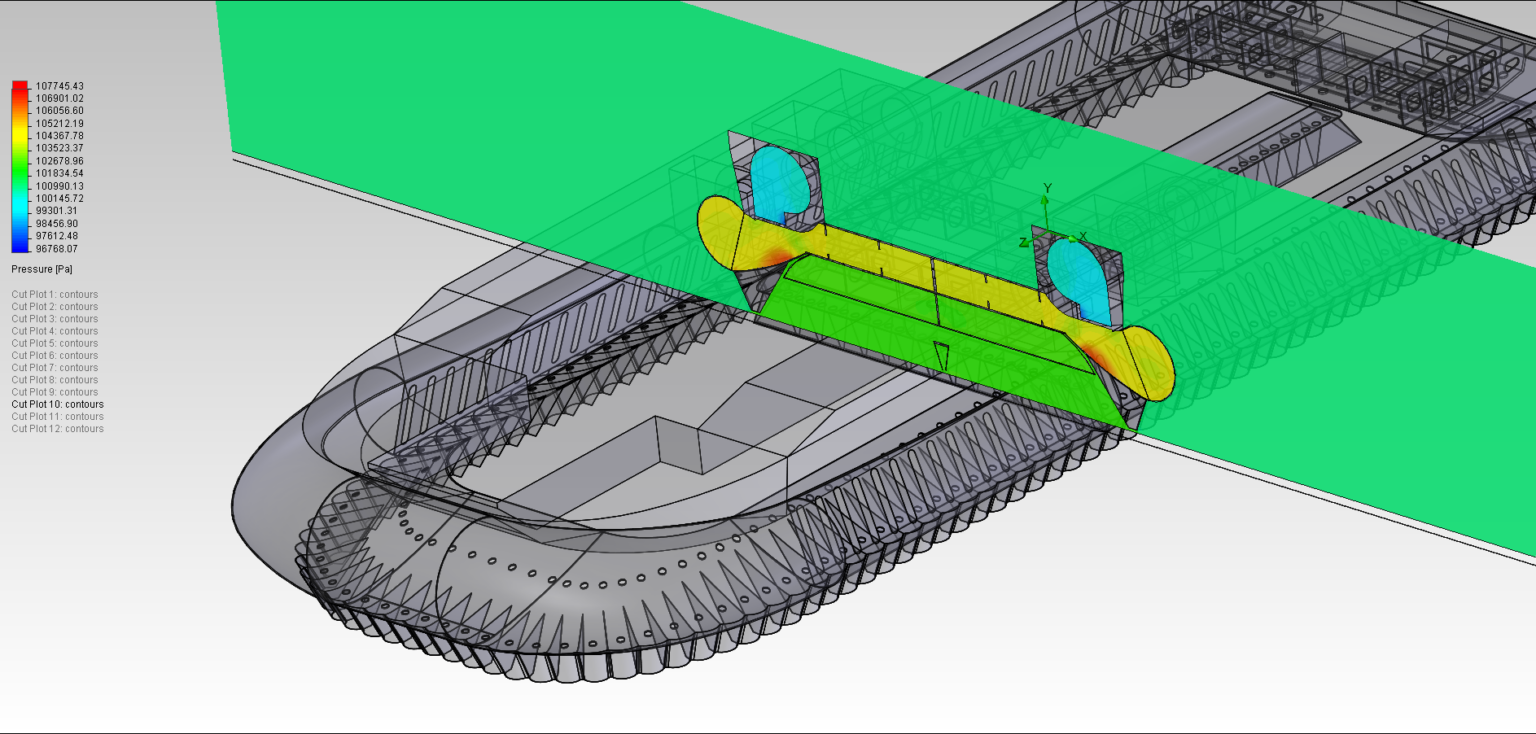

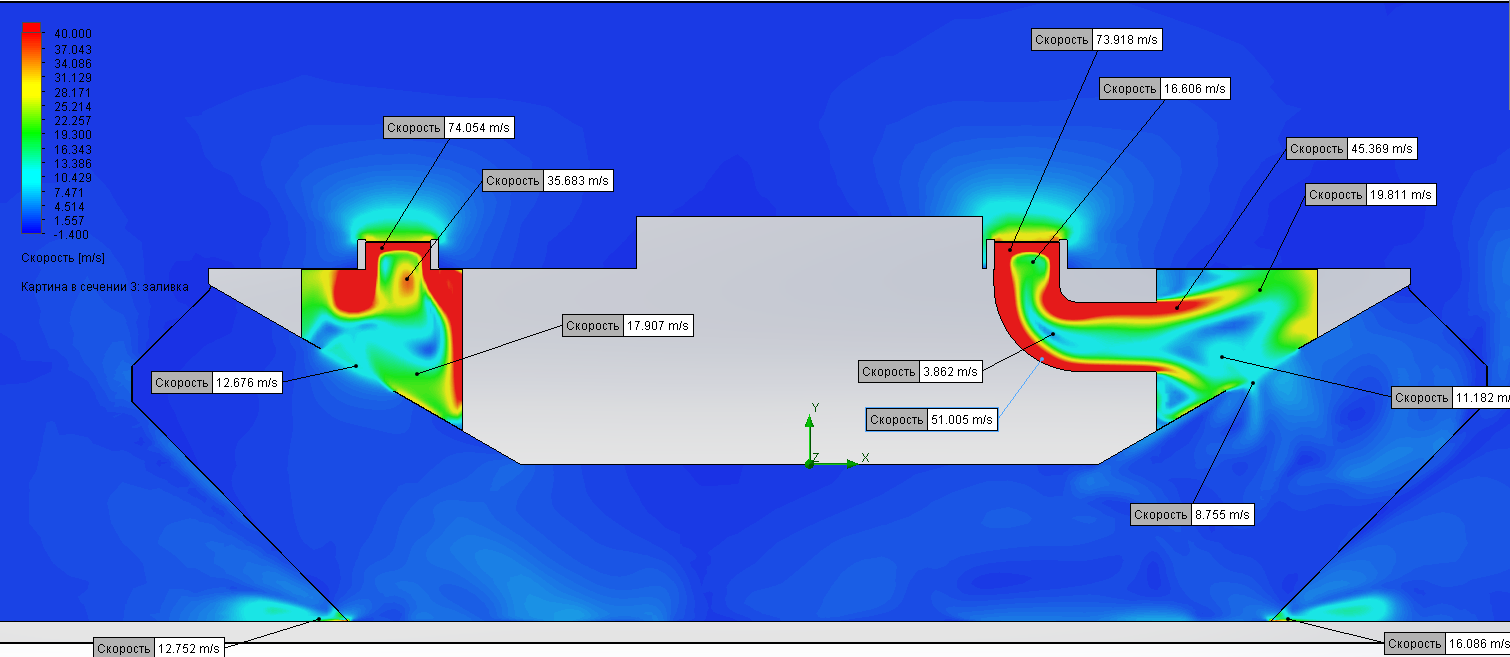

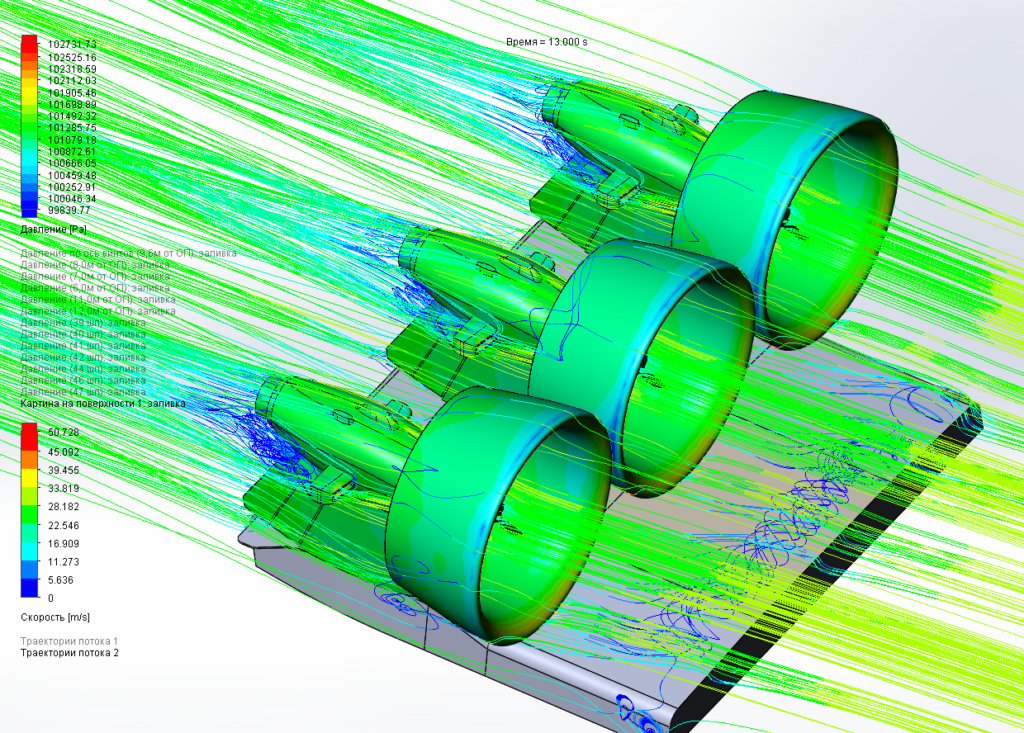

We actively use CFD for analysis and optimisation in the design of ships and their components. Computational Fluid Dynamics plays a particularly important role in the design of hovercrafts, where optimisation of the overall mass of the vessel, the shape of the hull or air ducts, and energy consumption are critical to the success of the project.

What is CFD?

CFD is a field of computational mechanics that uses numerical methods and algorithms to solve and analyse problems related to fluid or gas flow. Using CFD it is possible to model and analyse complex flows of water, air and other fluids, predict the behaviour of structures that interact with aero- and hydrodynamic flows, and investigate the effects of various factors on ship performance.

Advantages of Using CFDs

- Accuracy and Efficiency: CFD enables accurate calculations and analyses, which improves design efficiency and reduces research and testing time.

- Design Optimisation: With CFD, various aspects of ship design can be analysed and optimised, contributing to more efficient, cost-effective and safer ships.

- Cost Reduction: Minimising problems at the design stage reduces the cost of manufacturing and testing prototypes.

Why is CFD Important for Ship Design?

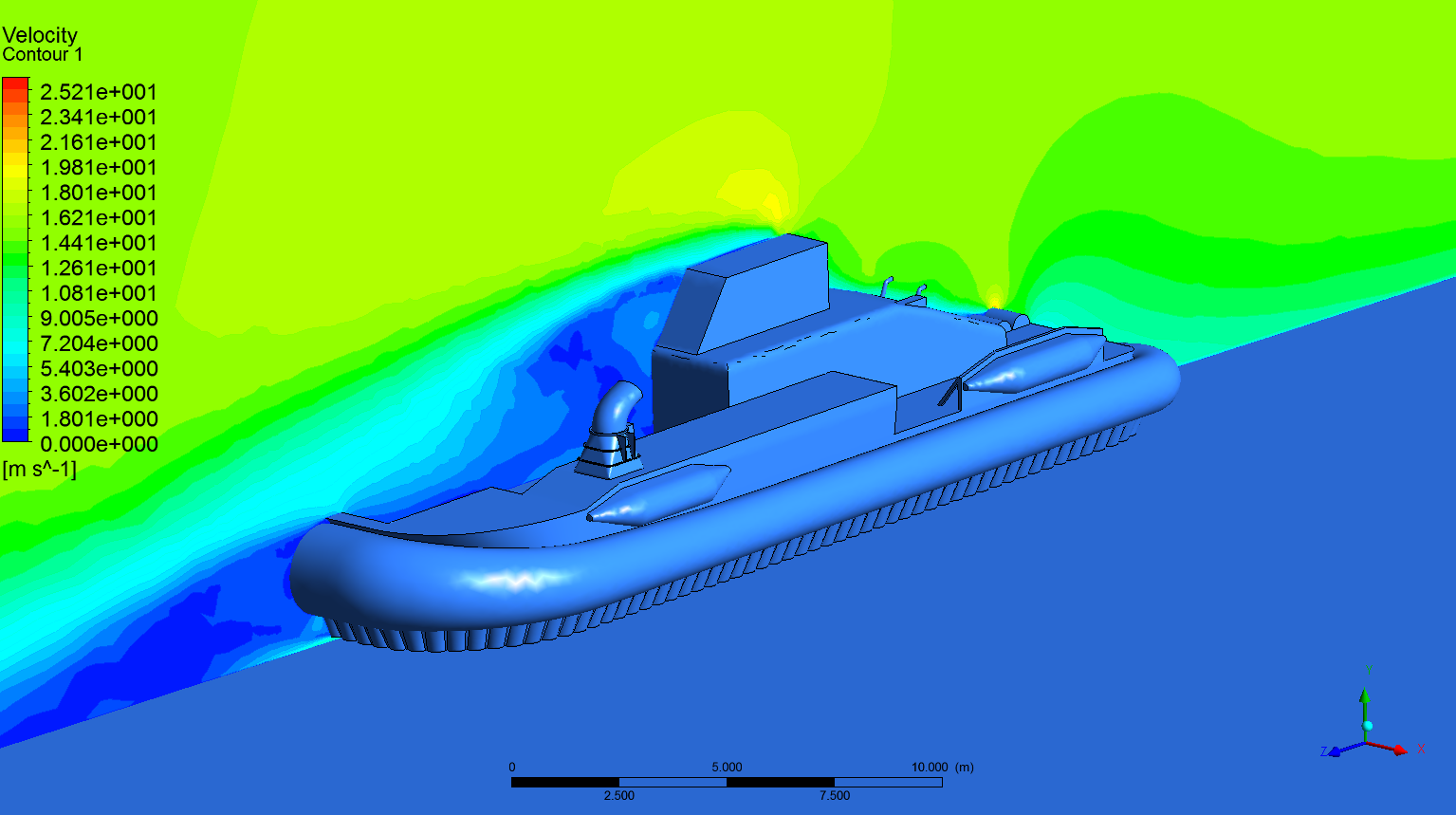

The application of CFD allows engineers and designers to visualise and analyse fluid flow around a vessel or its parts (sometimes in real time), conduct tests and simulations under different conditions, and optimise the design of the vessel to increase its efficiency, stability and safety. This significantly reduces the time and resources required to test prototypes and improves the quality of the final product.

Application of CFD in IMT Design Bureau LLC

Engineers at IMT Design Bureau actively use CFD at all stages of ship design. From modelling the general hydrodynamic behaviour of the vessel to the analysis of specific elements such as rudders, propellers and hulls. Thanks to this, IMT Design Bureau specialists can predict and minimise possible problems related to hydrodynamics at the design stage, which significantly reduces risks and costs at subsequent stages of vessel development.

When designing hovercraft, CFD allows you to analyse and optimise the performance of the lift system, study the effects of various factors on hovercraft performance, and adapt the design to specific operating conditions. For each hovercraft, a unique hovercraft blower must be created. Computational fluid dynamics allows to create such blowers with specified technical characteristics at minimum weight and minimum overall dimensions.

Finalising

Application of computational fluid dynamics in ship design is not only a modern trend, it is a necessity for creating efficient, reliable and safe ships. IMT Design Bureau LLC is a professional in this field, actively using CFD to create innovative solutions in shipbuilding.

We believe in the future, where every vessel created using CFD will be an embodiment of engineering excellence and technological progress.